Products

Welcome To Tomorrow

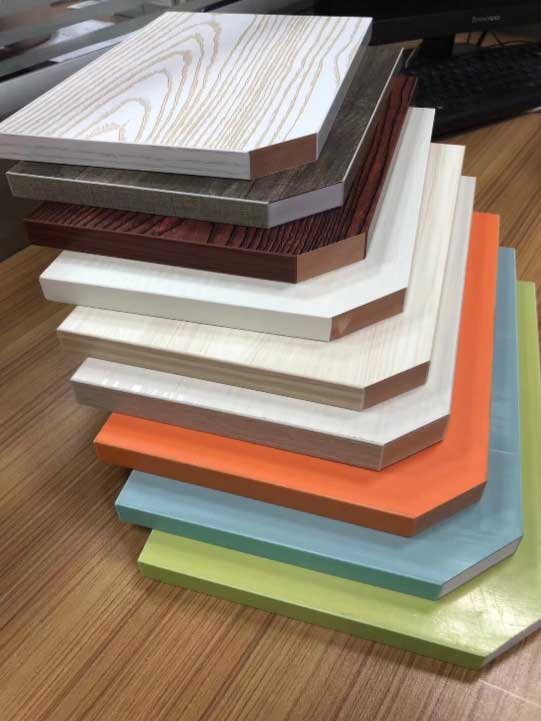

18MM Pre Laminated Designer WPC/PVC

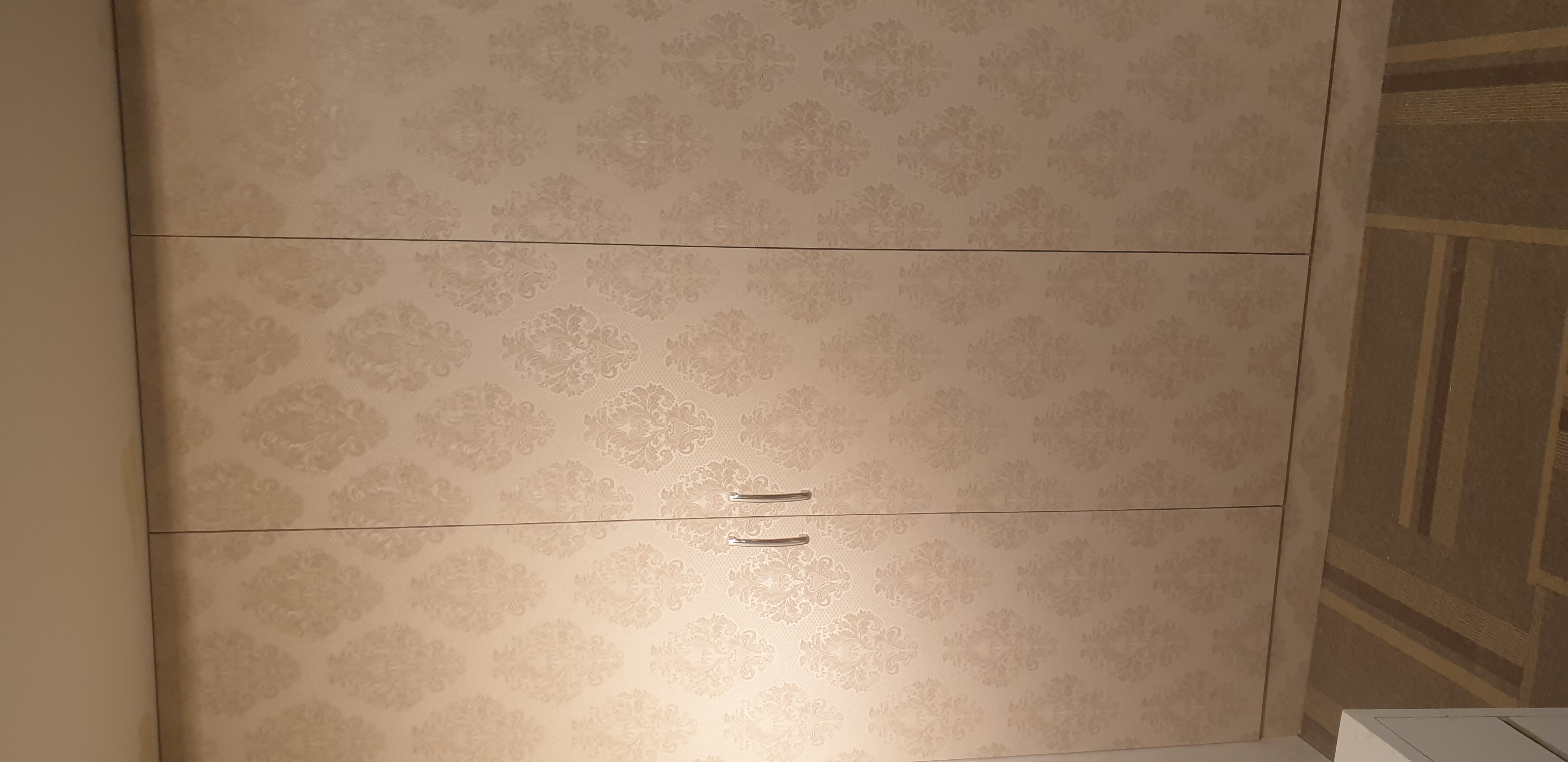

Pre laminated Decorative WPC/PVC has a decorative laminate surface that is attached at the time of manufacturing. A decorative laminate is added over the board surface to increase the aesthetic value of the surface by ensuring the look and feel is completely changes. This lamination also helps increase the board's resistance towards moisture, and the ability to withstand wear and tear.

Pre laminated WPC/PVC are often found being categorized into following two types:

- OSL or One sided lamination – A single side of the WPC/PVC is laminated, preferably the top surface, while the other side remains untouched.

- BSL or Both sided lamination – It differs than OSL since, both the top and bottom surfaces pre laminated at the manufacturing time itself. This makes BSL a costlier procedure as compared to OSL.

- OVERVIEW

- Technical information

- gallery

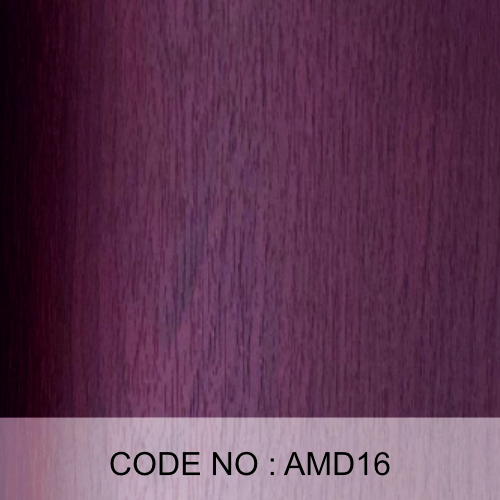

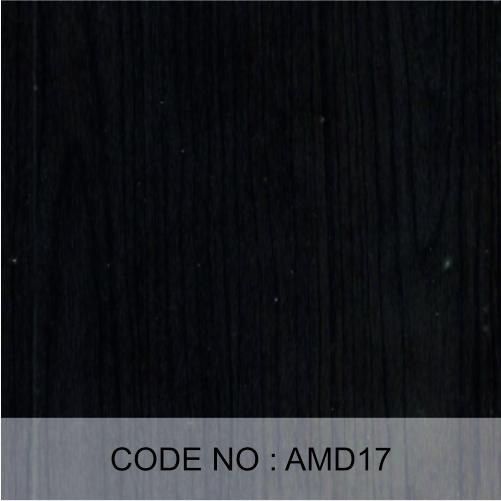

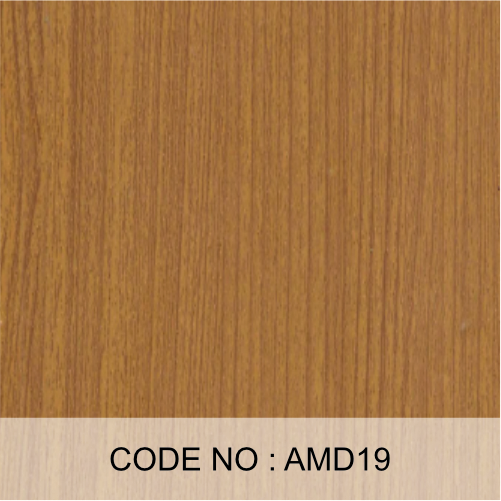

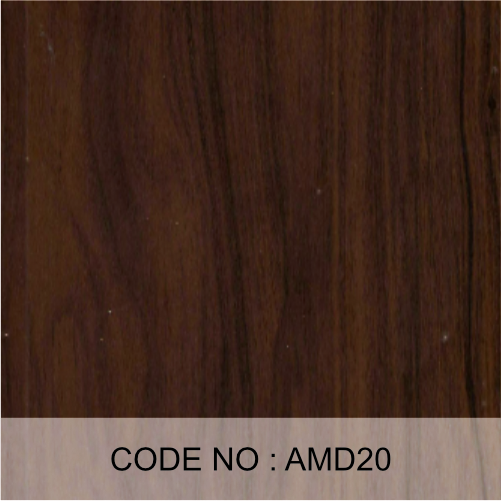

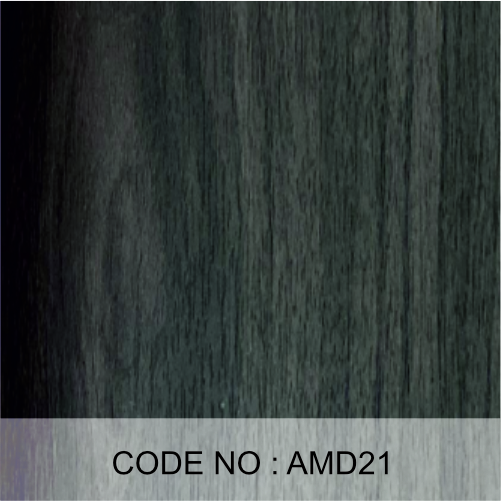

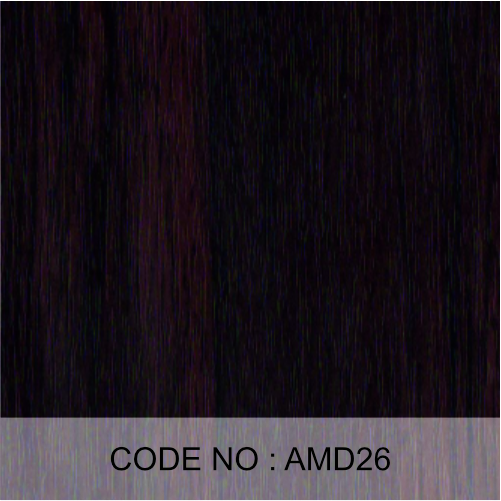

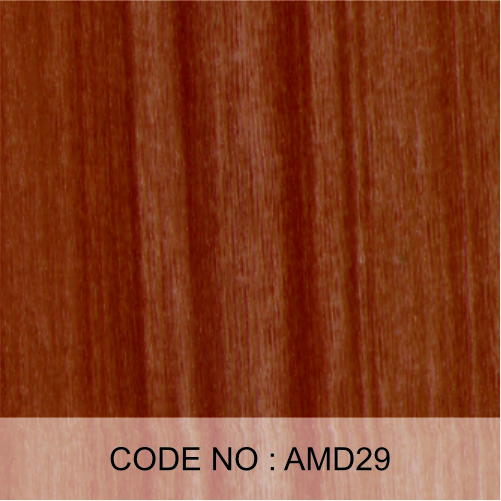

- Shades

- Downloads

- Enquiry

Pre Lamination process

A PUR hot melt lamination uses a high pressure Hot glue which is a lining and pressing machine. It is highly useful for pre laminating tasks associated with the WPC/PVC. A decorative PVC or PET foil is then pressed over the WPC/PVC surface which is done utilizing the capability of the PUR hot melt lamination machine.

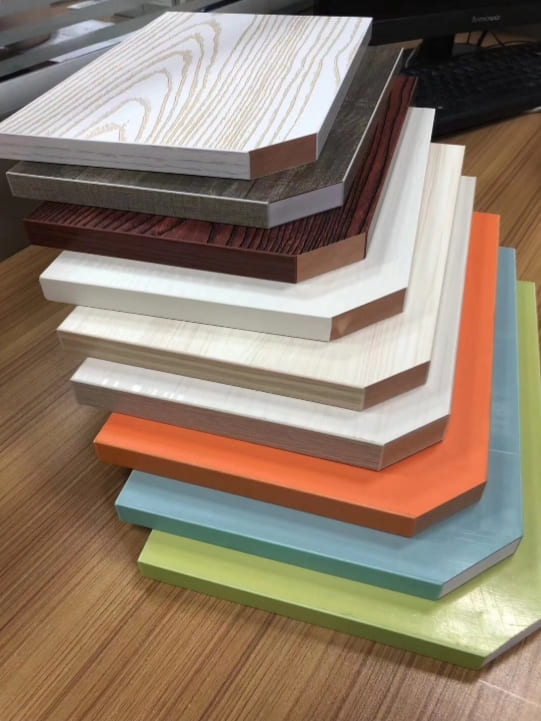

The usual and bland WPC/PVC get and upgrade when adorned with colorful shades, designs, as well as textures. The designs then replicate the whole look and feel of the wood which is quiet prominent amongst the customers.

WHY Pre laminated decorative WPC is better?

In case plywood is used the decorative laminates are usually purchased separately, these are then cut to size and glued together over the surface of plywood by experienced and reliable carpenters. The decorative laminates that are used along with the plywood generally come in a thickness of 2 to 2.5 mm. These have another characteristic that these are made of a brown Kraft paper which is prepared utilizing phenolic resin, along with a decorative paper being saturated with the help of melamine resin.

On the other hand, in the case of pre laminated WPC/PVC thickness of total lamination is significantly minimized, it is due to the fact that brown paper holds no significance. The PVC foil is then directly bonded over the surface of WPC/PVC.

Applications

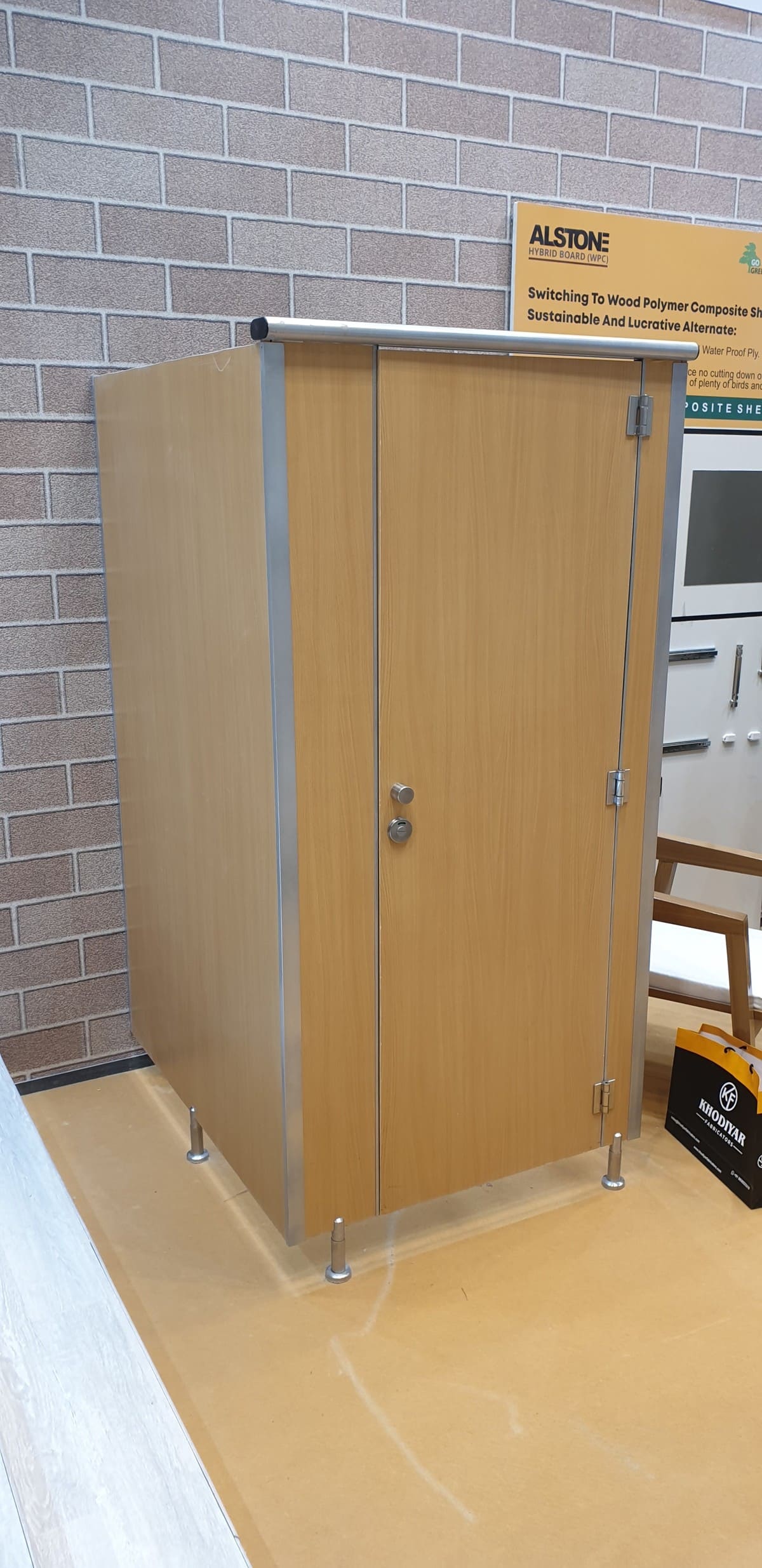

The Pre laminated WPC/PVC find their applications in various spheres, from ready-made furniture to false ceiling, wall panels, kitchen cabinets, and partitions. WPC/PVC are strong and as heavy-duty as plywood or block boards. These boards are significantly lower in price as compared to the plywood sheet of the same size.

Advantages:

- 100% Water Proof & Termite Proof

- Calibrated Boards

- Ready to use and easy Doors

- Solid Structure with No Gaps

- Economical

- Color stability and better protection from UV rays

- Sound insulation.

- Easy to maintain and install

- Higher resistance to damage

- Strong and flexible as compared to traditional wood products

- Standard tools can be administered upon

- Stability against moisture also suitable for temperature ranging from -40 to 60

- Eco-friendly with no formaldehyde, hence, no harm to any living organism.

- Recyclable and hygienic.

- Waterproof

- Light in weight

- Resistance to fight bugs

- Resistance towards oxidation

- Erosion

- Climate stability with least amount of contraction or expansion.

- Shower-safe technology

- Matching edge bends are provided

- Excellent Capacity to hold the screws and hence keep structure in shape.

- Sturdy construction and durability

- Durability, dimensionally stable and optimum level of strength

- Easily available and ensures prompt delivery.

| Dimensions | 4x8 Feet |

| Colors | 100+ Colors available as per shade card |

| Thickness | 18mm |