Products

WPC/PVC Shuttering Ply

WPC/PVC Shuttering Ply

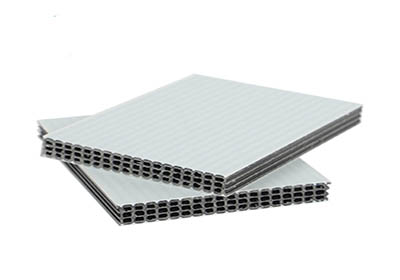

Alstone WPC/PVC Shuttering ply, an eco-friendly and energy-efficient product made of WPC/PVC, combines nanotechnology in macromolecules. WPC/PVC formwork is a brand new product following wood formwork bamboo-wood bonding formwork and large formwork made of all steel. The WPC/PVC formwork is efficient in energy and environmentally friendly; it can entirely replace traditional formwork made of steel, wood, or square wood. What's more, the amortization costs are meagre.

In light of the labour issue and cost of the system for shuttering ply, Alstone Industries was concerned about the cost of labour and formwork. So, Alstone Industries decided to design an alternative method for shuttering that could assist the industry in reducing the cost of construction and create a simple system to set up and dismantle and handle. For the first time in India, we developed a WPC/PVC Shuttering ply to overcome many of the issues mentioned in the previous paragraphs.

- OVERVIEW

- Technical information

- gallery

- Downloads

- Enquiry

Cost Analysis of Alstone WPC/PVC Shuttering Ply

This system gives more than 50 repetitions; hence running cost is low. The final RCC work will get a smooth finish with a minor joint line that does not require plaster. One can do putty & paint it. With this system, one can save @ 16 / sq. ft. if you don’t do plaster and hence it is cost-effective.

– This system is made from special grade WPC/PVC and hence no chemical reaction takes place nor does the material stick to it. Because of this property, you cannot get any patched on the RCC finish. Also, the gap between two plates is so negligible that no water nor cement gets leaked out at the time of RCC & it gets cured from the bottom of the plate also, which enhance the final quality of RCC casting.

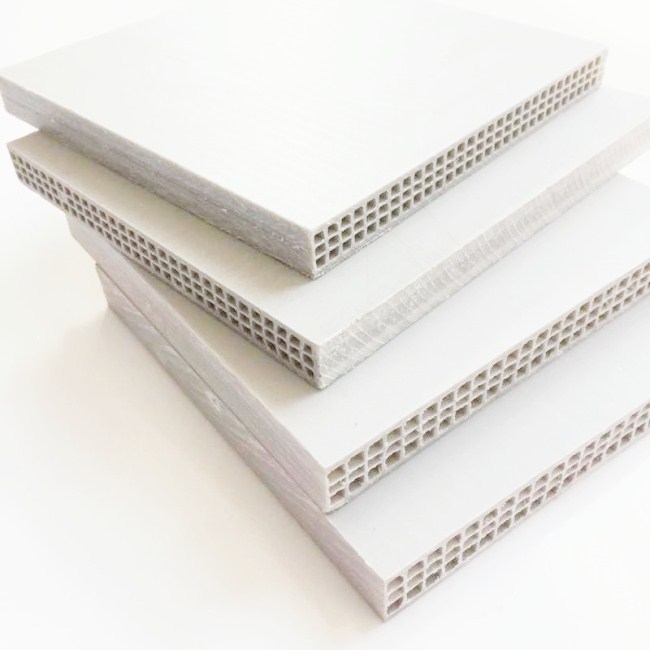

– Comparatively, our foam systems are very less in weight compared to conventional M.S. Plate (1/4th ) and Plywood (1/2). Hence it is very easy to install, dismantle, transport from one place to another. Due to easy plugging systems & east to fit makes this foam shuttering system is the most labor-friendly.

– By using Alstone WPC/PVC shuttering sheets one need not nail or apply oil to the plates before casting RCC. Due to auto-leveling of plugging systems the plates are automatically leveled. Hence 30 % time is saved in assembling & also while dismantling the same.

– All existing traditional scaffolding systems can be use in Alstone WPC/PVC Shuttering ply comfortably. You can cast Slab, Beam & Column, etc. A lot of the parts in the Shuttering ply are supportive to each other and you can cast a beam from 9 inch to 21 inch by this same plate by simply adjusting the locking systems.

– Alstone WPC/PVC shuttering ply is made from waste products which are recycled and it’s long lasting and gives more than 50 repetitions. It replace plywood’s which consumes trees and M.S. which consumes iron ore from our planet earth. Our products help in preventing this precious metal from our earth.

– After every usage of Alstone WPC/PVC Shuttering ply once can easily clean the plates by water. Where as in M.S. plate one have to apply oil to clean the M.S. surface plates. In WPC/PVC shuttering sheet if any breakage occurs by mishandling it can be very easily sealed by low voltage hot air gun.

Advantages:

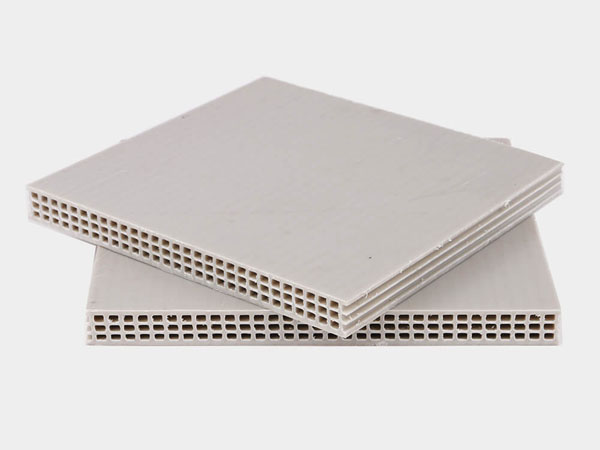

Lightweight, high strength, high hardness, impact resistance, wear resistance. 2. Surface is smooth, bright and clean; Concreting and forming effect is good. 3. No absorption of moisture, no deformation, no mildew; Long-term immersion stratification in the water, no bubbles, sheet size stability, especially suitable for underground and damp environment. 4. Good toughness. WPC/PVC formwork sheet could be used as cambered special-shaped formwork. 5. Acid and alkali resistance, corrosion resistance, it doesn’t need to do any preservative treatment both in using and storing the formwork, and do not pollute the concrete surface. 6. The reusable time for WPC/PVC Foam Work sheet can reach more than 50 times, long service life.7.WPC/PVC formwork in construction was easily install and removed, only tapping not releasing agent .

How to Use Alstone WPC/PVC Formwork

- Method of use WPC/PVC building formwork as well as wooden formwork, WPC/PVC building formwork reinforcement direction with batten direction placed in cross shaped.

- No need to smear the mold release agent before using building WPC/PVC formwork construction.

- When cast-in-place the flat plate, spacing between the keels should be 20 ~ 25 cm, and the spacing between the wall plate and keels hould be 10 ~ 20 cm. WPC/PVC building formwork in construction don't need releasing agent.

- The seam-line between WPC/PVC building formwork in construction should be taped.

- The length of nail should not be too long, generally about 30 ~ 35 mm.

- The strength to drive nails should be moderate.

- When removing the reusable WPC/PVC formwork, please start from the small part of one end, the support and the plates should be removed at the same time aiming at preventing the template widespread drops, don't let the corner drop on the ground vertically.

- The WPC/PVC building formwork accesses to be mixed used with wood veneer, bamboo veneer and other material plate.

| Dimensions | 4x8 Ft |

| Colors | Black |

| Thickness | 14 mm |